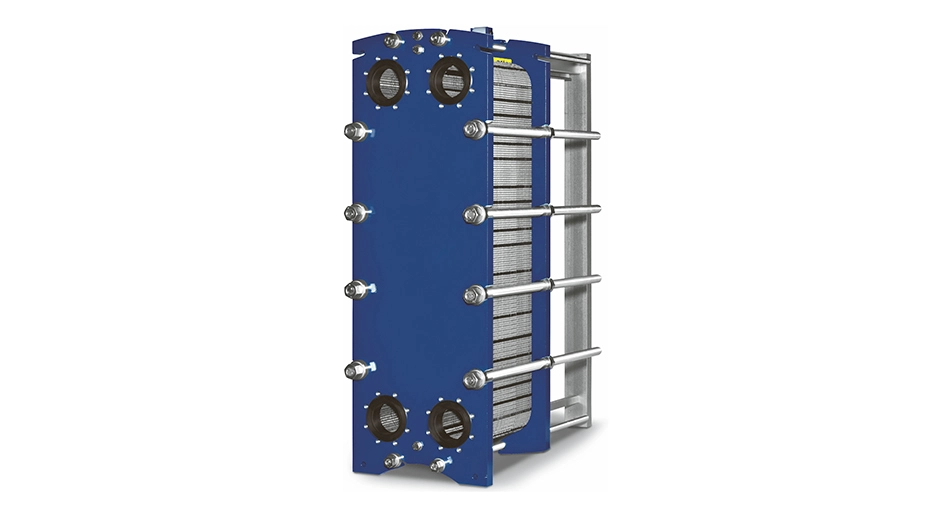

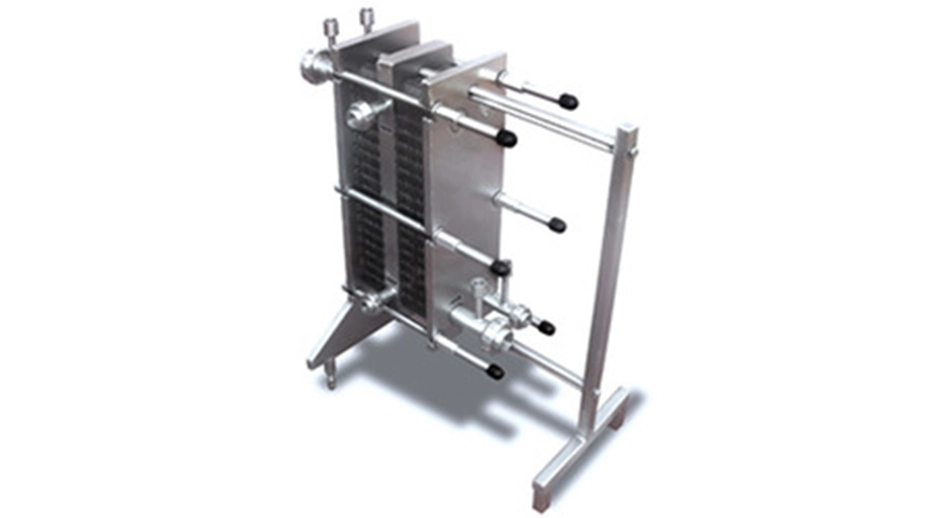

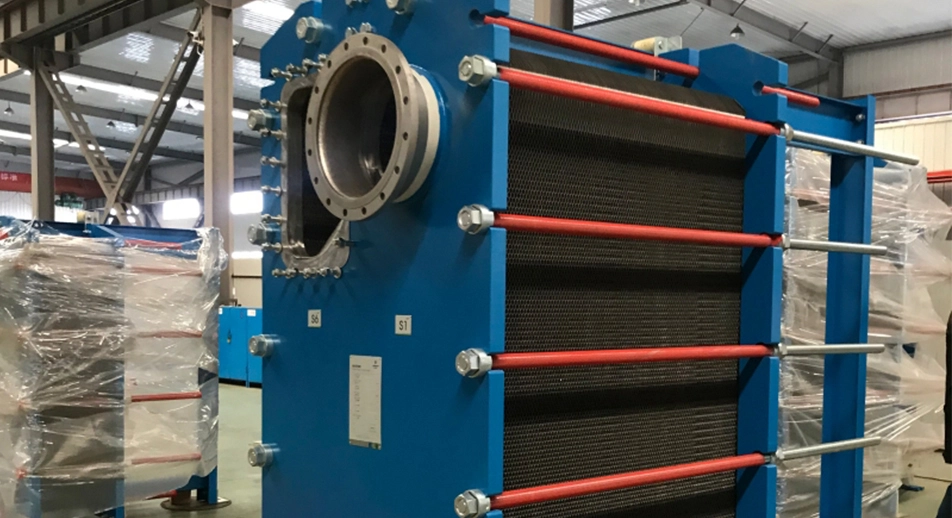

Plate heat exchangers are advanced and versatile devices that facilitate efficient heat transfer between two or more fluids. Their compact and modular design consists of multiple plates stacked together, creating passages for the fluids to flow through.

Plate heat exchangers utilize thin plates with alternating channels to facilitate heat transfer between two fluids. The plates provide a large surface area for efficient heat exchange. The fluids flow through separate channels, with one fluid passing through even-numbered channels and the other through odd-numbered channels. Heat is transferred from one fluid to the other through the thin plates, promoting effective thermal exchange.

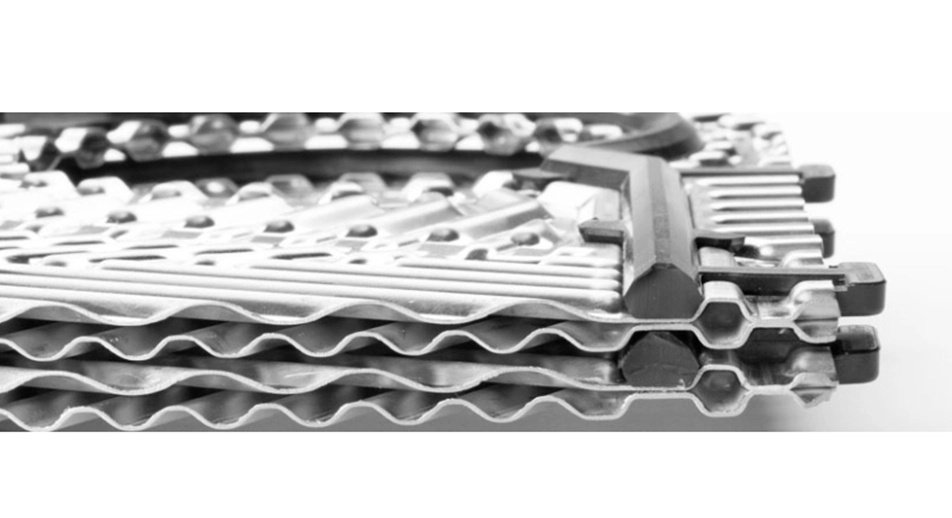

The plates in a plate heat exchanger are designed with corrugations or ridges. These corrugations create turbulence in the fluid flow, disrupting laminar flow and increasing heat transfer efficiency. Turbulence promotes better mixing and minimizes the formation of boundary layers, allowing for higher heat transfer rates. The turbulent flow in plate heat exchangers ensures that the fluids come into close contact with the heat transfer surface, maximizing the effectiveness of heat transfer.

Gaskets are used to seal the edges of the plates, ensuring that the fluids flow through their respective channels without leakage or mixing. The gaskets also provide thermal insulation between the plates, minimizing heat losses through conduction. The sealing and insulation properties of the gaskets are essential for maintaining the integrity of the heat exchange process and optimizing the efficiency of the plate heat exchanger.

Tel

Tel